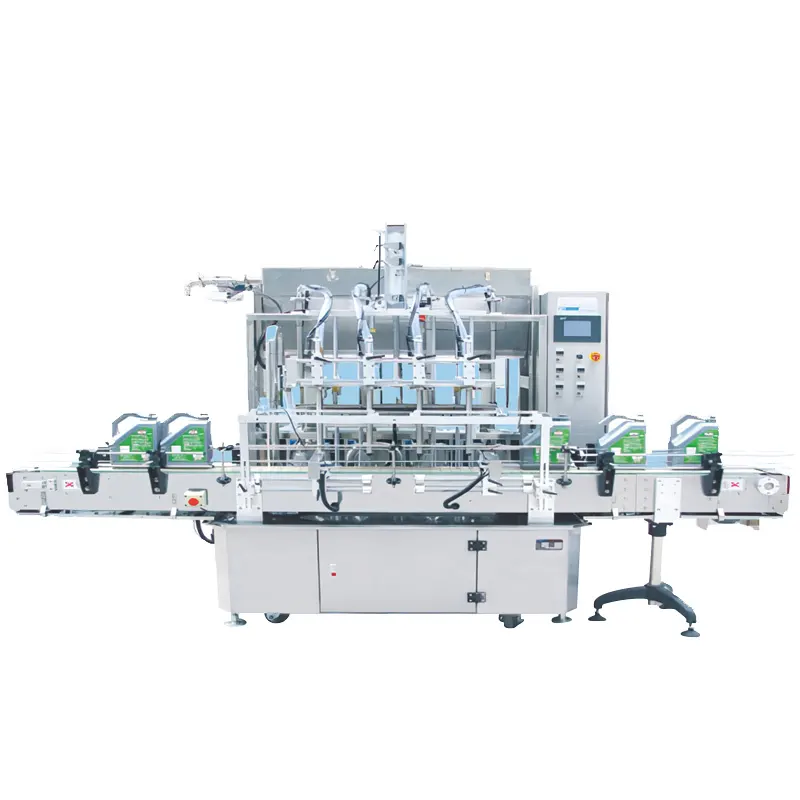

Top Features of an Automatic Rotor Lobe Pump Filling Machine Explained

In the fast-paced world of industrial manufacturing, precision, efficiency, and safety are paramount. Enter the automatic rotor lobe pump filling machinea game-changing technology that has transformed traditional filling processes into sleek, reliable operations. These machines offer a blend of precision, high throughput, and advanced safety features, making them an essential tool for modern industries. Lets dive into the key features that make automatic rotor lobe pump filling machines the future of industrial filling.

Precision in Filling

When it comes to precision, automatic rotor lobe pump filling machines are in a league of their own. The design features a rotating rotor with lobes that create a tight seal around the product, ensuring consistent and accurate fills. This precise mechanism is particularly crucial for industries like pharmaceuticals, where even minor inconsistencies can affect product efficacy and patient safety.

For example, in the pharmaceutical sector, automatic rotor lobe pumps guarantee that each vial or bottle is filled to the exact weight or volume, ensuring uniform dosing and patient safety. By minimizing variance, these machines help maintain the integrity of the product and enhance patient outcomes.

Superior Efficiency and Productivity

These machines stand out as a testament to automations efficiency. Automated systems reduce the need for manual intervention, significantly increasing throughput. A single rotor lobe pump can fill hundreds of containers per hour, far outpacing manual systems. In a beverage manufacturing plant, an automatic rotor lobe pump can fill thousands of bottles in a day, while a manual system might struggle to keep up.

This efficiency not only boosts productivity but also reduces labor costs, making rotor lobe pumps a cost-effective choice. By automating the filling process, manufacturers can focus on other critical tasks, leading to overall operational improvements.

Versatility and Application Scope

The rotor lobe pumps versatility is one of its greatest strengths. These machines can handle a wide range of products, from powders and liquids to semisolids, in various packaging types and sizes. Industries such as food processing, pharmaceuticals, and chemical manufacturing benefit significantly from this adaptability.

For instance, in the food industry, rotor lobe pumps can fill different products like yogurt pots, juice cartons, and milk bottles. This flexibility ensures that manufacturers can meet diverse packaging and product needs, enhancing their market reach and operational efficiency.

Robust Safety Features

Safety is a key feature of automatic rotor lobe pump filling machines. Overfill protection, leak detection, and ergonomic designs are just a few of the safety features built into these machines. Overfill protection ensures that containers do not exceed their capacity, preventing spillage and waste. Leak detection systems alert operators to any unintended leaks, ensuring immediate action and minimizing product loss.

Ergonomic designs, on the other hand, prioritize operator comfort and reduce the risk of accidents. For example, an operator can easily adjust settings without straining, making the operation safer and more comfortable. These safety measures are crucial in ensuring that both the product and the workforce are protected.

Simplified Maintenance and Lower TCO

Maintenance is easier and more efficient with automatic rotor lobe pump filling machines. The machines require minimal parts and are designed with ease of access in mind, making routine maintenance quick and simple. User-friendly interfaces allow operators to monitor performance and make necessary adjustments, further reducing downtime.

By minimizing maintenance costs and operational disruptions, rotor lobe pumps offer a lower Total Cost of Ownership (TCO) compared to traditional manual systems. This cost-effectiveness is a significant advantage for manufacturers looking to optimize their operations.

Future Trends and Innovations

The future of rotor lobe pump filling machines is bright, with ongoing advancements in technology. Integration with Internet of Things (IoT) and artificial intelligence (AI) is on the horizon, enabling real-time monitoring and predictive maintenance. These innovations promise even higher efficiency and reliability.

For example, smart sensors can monitor machine performance in real-time, alerting technicians to potential issues before they become critical. This level of integration enhances productivity and ensures sustainable operations. Additionally, future designs may incorporate sustainable materials and energy-efficient technologies to align with global environmental initiatives.

Benefits Recap

In conclusion, automatic rotor lobe pump filling machines are revolutionizing industrial filling processes with their precision, efficiency, versatility, and advanced safety features. These machines offer a higher standard of performance and sustainability, making them a valuable asset across various industries. As the industry continues to evolve, rotor lobe pumps are set to play an even more critical role, driving efficiency, safety, and environmental responsibility.

Embracing these machines is not just a technological advancement; it is a strategic move towards a smarter, safer, and more sustainable future in manufacturing. By adopting automatic rotor lobe pump filling machines, manufacturers can achieve unparalleled precision, efficiency, and safety, ensuring a competitive edge in the rapidly changing industrial landscape.