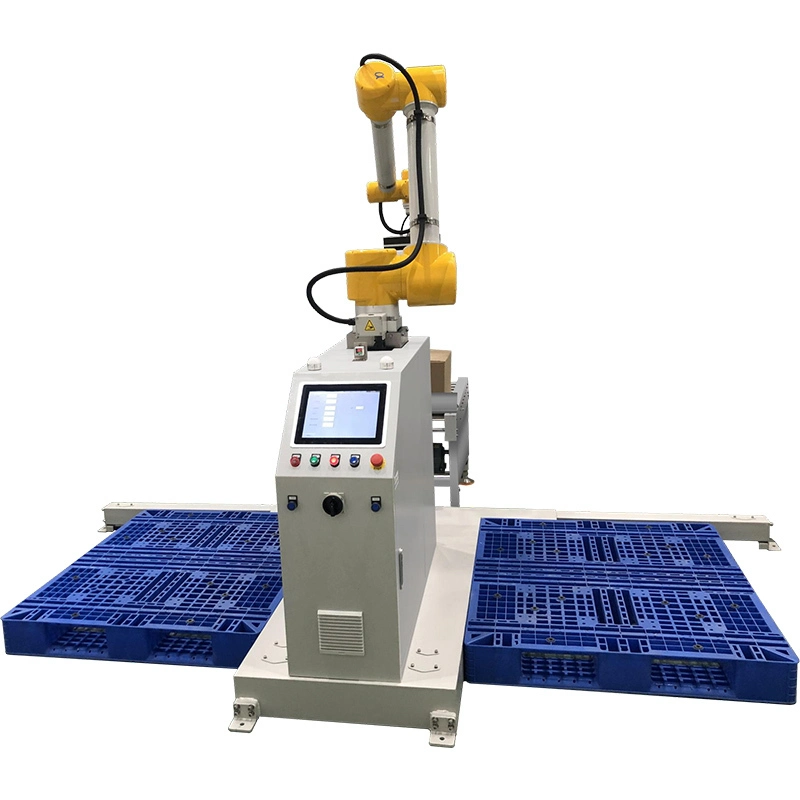

Alpha-Robot collaborative Robot palletiser

Collaborative Palletizer Workstation is a small goods- handling expert tailor-made for food, medicine, 3C, food, printing, daily chemical and other industries. Visual programming design only takes 5 minutes.

Model: Parameter for APR-C20L

Speed: 5-12 cycles / min

Effective load bearing: 20KG

Floor area: 3590mm*1725mm

Power: 220V 3KW, 1Ph,50Hz

Working radius: 1600mm

Applicable carton range: L:200-500mm; W:200-500mm; H: 200-400mm(apply to 1200mm*1200mm)

|

Model |

Parameter for APR-C20L |

Parameter for APR-C20H |

|

Speed |

5-12 cycles / min |

5-12 cycles / min |

|

Effective load bearing |

20KG |

20KG |

|

Floor area |

3590mm*1725mm |

3590mm*1725mm |

|

Power |

220V 3KW, 1Ph,50Hz |

220V 3KW, 1Ph,50Hz |

|

Working radius |

1600mm |

1600mm |

|

Applicable carton range |

L:200-500mm; W:200-500mm; H: 200-400mm |

L: 200-500mm; W: 200-500mm; H: 200- 400mm |

|

Palletizing height |

standard 1.6Meter |

2.2Meter |

|

Pallet size |

Maximum 1200mm*1200mm Material: plywood, plastic, wood |

Maximum 1200mm*1200mm Material: plywood, plastic, wood |

|

Placement rules |

AB stack |

AB stack |

|

Barometric pressure |

0.4-0.8 Air consumption: 400nl/min |

0.4-0.8 Air consumption: 400nl/min |

|

Re-read positioning accuracy |

±0.04 |

±0.04 |

Product Introduction

Collaborative Palletizer Workstation is a small goods- handling expert tailor-made for food, medicine, 3C, food, printing, daily chemical and other industries. Visual programming design only takes 5 minutes. After entering the information within a few minutes, the products/cartons can be stacked on the wooden board to realize unmanned handling.

The visual programming design that does not pick people is convenient for the operator to easily operate the robot; the end of the high-load design. The end effector can grab up to 20KG heavy products. The machine has flexible deployment, small footprint, simple wiring, convenient maintenance and fast efficiency. It can stack 8-10 boxes in one minute.

Characteristics

Simple operation

With touch screen design, it only needs to manually enter and save the parameters to realize unmanned handling;

Simple operation process

Preparation - Palletizing mode setting - A palletizing - B palletizing - complete;

Both left and right can be stacked Labor saving

The palletizing operation of the goods is completed by the machine instead of the manual;

Easy maintenance

Precision parts, only the suction cup needs to be replaced after 300,000 times of use;

High safety factor

No need to use fences for safety isolation, with high reliability and safety;

Flexible Expansion

Can be combined with unsealing machine, carton labeling machine and other assembly lines to provide customers with an overall solution for packaging goods.

Operating system

With 5 Axis

Austria Keba control system

Annovance 12 inch color touch screen

Build in anti collisione sensor

Company profile

Alpha-Pack Enterprise Limited was established in 1991 in Hong Kong. Alpha-Pack is a comprehensive enterprise that dedicated in packaging machinery in last 20 years; it combines R&D, production, marketing and service together.

Since the company has been founded, Alpha-Pack cooperated with many famous European packaging machinery manufacturers to make the packaging machinery for worldwide market. As the name in Chinese “Ouhua”,means we made the machine with European standard but in Chinese manufacturing cost.

Thanks to the trust from all the business partners, customers and staffs, Alpha-Pack has been grown as one of the biggest packaging machinery manufacturing group in South China, with more than 80,000 m2 manufacturing workshops in China and Europe, Alpha-Pack became the leading packaging manufacturer in China for the following categories of packaging machineries:

◈ Vertical Form Fill Seal and Flow Wrapper

◈ Thermo sealing & MAP

◈ Flow wrapper

◈ Pre made pouch filling and sealing machine

◈ Filling, capping and labeling machine

◈ Vacuum Machine