Ultrasonic Tube Sealing Machine Alpha-Pack Brand

Product details of the ultrasonic tube sealing machine

Quick Overview

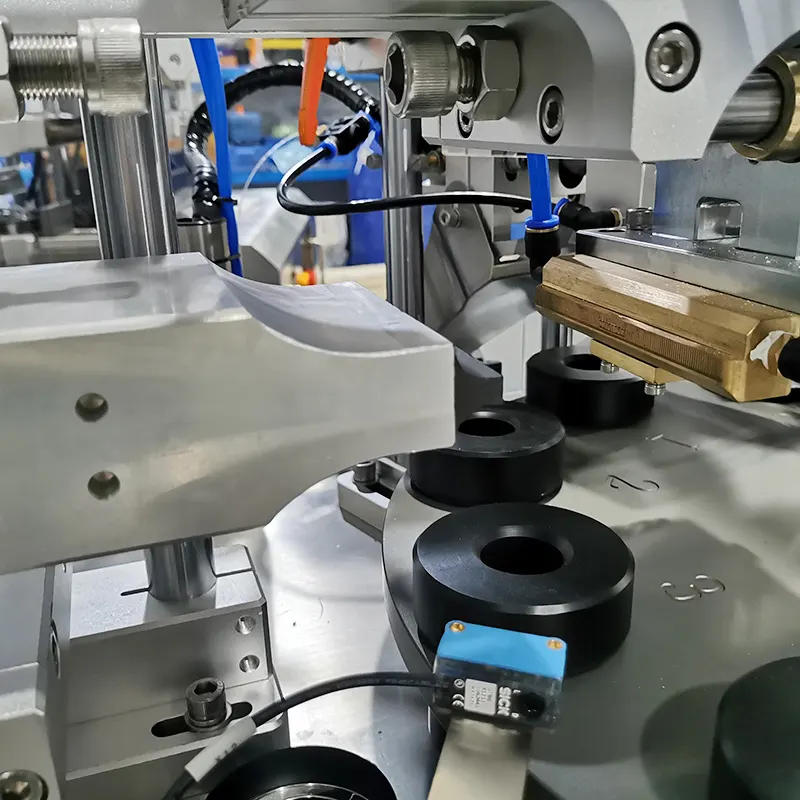

ultrasonic tube sealing machine has a reasonable design, excellent performance, and reliable quality. It is easy to operate and maintain with high working efficiency and good safety. It can be used for a long time. Alpha-Pack ultrasonic tube sealing machine has an appearance design that follows the market trend. Product performance and quality are in line with industry specifications. ultrasonic tube sealing machine is commonly used in many industries including food and beverage, pharmaceutical, daily necessities, hotel supplies, metal materials, agriculture, chemicals, electronics, and machinery. Promising application prospect and tremendous market potential can be seen from ultrasonic tube sealing machine.

Product Description

Compared with other products in the industry, ultrasonic tube sealing machine has more obvious advantages which are reflected in the following aspects.

| Technical Parameters | |||

| Production capacity | 40 pieces/min | Motor power | main motor 1.1kw |

| Filling capacity | 5-250ml | heat sealing power 3kw | |

| Hose diameter | 15-50mm | Working pressure | 0.60MPa |

| Hose length | 50-220mm | Air consumption | not less than 600L/min |

| Filling error | ≤±1%; | Equipment weight | 750kg |

| Dimensions | 1700*1000*2000mm | ||

| ITEMS | BRAND | ORIGIN | ITEMS | BRAND | ORIGIN |

| PLC | DELTA | TAIWAN | Main Pneumatic component | AIRTAC | TAIWAN |

| Frequency Changer | DELTA | TAIWAN | Air-break switch | CHNT | CHINA |

| Touch Screen | EVIEW | TAIWAN | Emergency Swift | Schneider | FRANCE |

| Encoder | Omron | JAPAN | Power switch | Schneider | FRANCE |

| Hot Air Generator | Leiste | Switzerland | Power lock | Schneider | FRANCE |

| Thermometer MODE | DELTA | TAIWA | Power indicator | Schneider | FRANCE |

| Proximity switch | SICK | GERMANY | Ac contactor | Schneider | FRANCE |

| Color Code Sensor | PANASONIC | JAPAN | Material Level Sensor (optional) | P+F | Germany |

| Air Pressure Control System | Omron | JAPA | Material contact parts | 316L Stainless Steel | CHINA |

| Change Speed Motor | WANNAN | CHINA | Machine Structure | 304 Stainless steel | CHINA |

1. The mechanical transmission part is closed below the platform, which is safe, reliable and pollution-free;

2. The filling and sealing part is installed above the platform, and the semi-closed non-static outer frame is visible in the cover, which is easy to observe, operate and maintain;

3. Stainless steel operation panel, plexiglass protective cover and door protection function installed;

4. Slant-hanging tube warehouse, which can accommodate more tubes,

5. The upper tube device is equipped with a vacuum adsorption device. After the upper tube interacts with the pressure tube device, the tube is inserted into the upper tube station;

6. Photoelectric benchmarking station, using high-precision probes, stepping motors, etc. to control the tube pattern to be in the correct position;

7. No tube, no filling, when the injection is finished, the air blowing device blows off the paste tail; anti-drawing, anti-drip filling

8. The heating temperature of the end sealing adopts (Leister hot air gun) internal heating at the end of the tube, and the external cooling device is equipped;

9. At the same time of sealing the end, the production batch number or date is automatically embossed on the position required by the process;

10. Waste cutting manipulator cuts the waste edge at the tail of the tube, and seals with special shapes such as right angle, R angle or arc;

11. Failsafe alarm, overload shutdown, water pressure protection, air pressure protection.

Company Introduction

Alpha-Pack (Heyuan) Co.,Ltd., which is located in shen zhen, is a comprehensive production-processing integrated company mainly providing Automatic filling,Vertical form film seal packing machine,shrink packing machine. Our company has always adhered to the business philosophy of 'seeking truth and being pragmatic, based on integrity, innovating and developing'. Besides, we carry forward our spirit of 'moving forward, pioneering and progressing, pursuing excellence'. We are committed to providing consumers with more and better products and services, with the undying aim to create a famous brand and become the industry leader. Alpha-Pack gathers a group of high-quality and high-efficiency talents. They have rich industry experience and exquisite production technology and greatly promote efficient business operation. Alpha-Pack is able to meet customers' needs to the greatest extent by providing customers with one-stop and high-quality solutions.

If you want to know more relevant product information, feel free to contact us. We are dedicated to serving you.